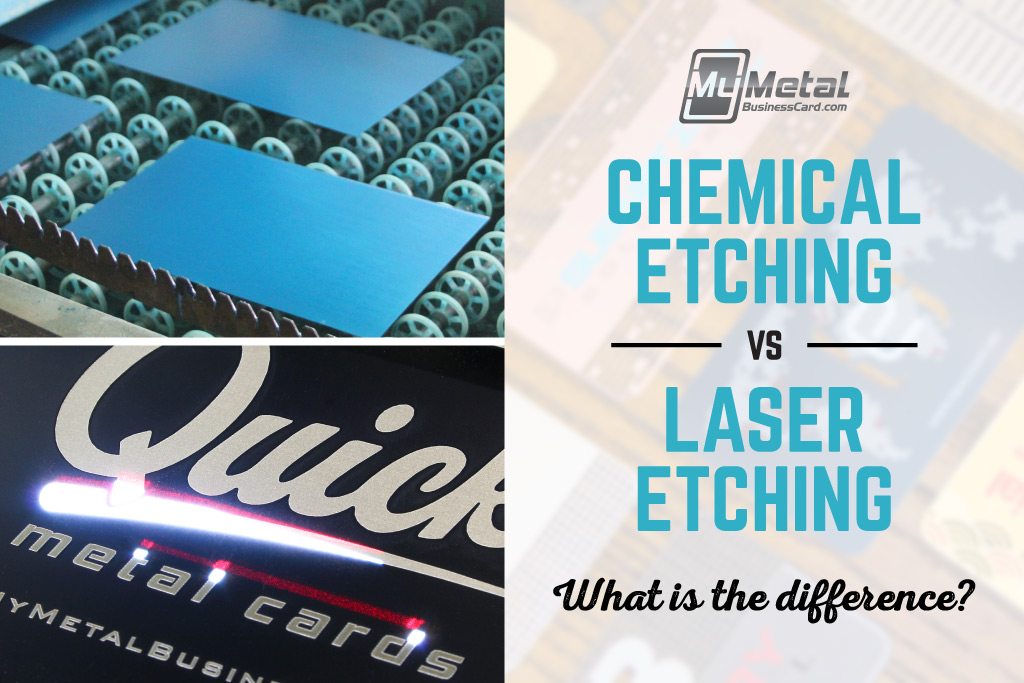

A common question we receive regarding our various production processes is: What is the difference between the etching methods we offer. There are two different processes we use to etch into the metal: Chemical Etching and Laser Etching. Both are available for Stainless Steel, Black Metal, Brass Finish and Copper Finish materials.

The main difference between the two is Chemical Etching creates depth,

while Laser Etching lightly etches the surface of the card.

During the Chemical Etching process, we take the custom artwork designed for you and create a ‘film-tool’ to make your cards out of sheets of stainless steel. Next we prep the stainless steel sheets for etching, and etch your cards in a series of acid-based solutions. As a result, the chemicals etch down approximately 10% into the card’s surface creating depth.

In the same way, any cut out areas will be chemically etched down 50% from the top and bottom of the metal sheet to be completely cut through. If there are areas to be etched and filled with color, we etch down in the card’s surface 10% and then fill it in with your screen-printed color.

It’s important to note Chemical Etching is one of the initial processes done before coating the cards black, brass or copper. For this reason, once an order is sent to production we are not able to make any changes to the artwork.

So how can you tell the difference?

Simply run your finger gently across the surface of the card.

If you feel a slight indentation, then it’s chemically etched.

If the surface feels smooth, then its laser etched.

Since all of our cards start off as high-grade 304 Stainless Steel, if you laser etch off the finish it will expose the steel underneath. An example of laser etched cards are our Quick Metal Cards. (Refer to the short video below.) Using state-of-the-art technology, the laser lightly etches the card surface giving the text and content a silver color which contrasts the finish of the card.

As you can see, the laser is extremely quick – perfect for expedited orders or variable data! In addition to offering a fast process, laser etching yields the best results for very detailed artwork.

Here are a few images showing both Chemical Etching and Laser Etching:

Stainless Steel Featuring Chemical Etching and Black Spot Color

Black Metal Featuring Chemical Etching Prior to Anodizing

Copper Finished Card Featuring Cutout Logo and Chemical Etched Design

Brass Finished Card Featuring Chemical Etching

Stainless Steel Card Featuring Laser Etched Content

Black Metal Card Featuring Laser Etched Design

Copper Finished Card Featuring Laser Etched Variable Data

Brass Finished Card Featuring Laser Etched Content

Bottle Openers Only Allow for Laser Etching Due to the Thicker Material

My Metal Business Card is passionate about offering you the highest quality metal business cards and custom metal products around! We understand not everyone is familiar with the extensive processes involved in making custom metal products. Leave the explanation to us! We enjoy sharing our processes with you – we’re here to answer any questions you may have. Simply call us at 714.213.8155 or email Sales@test.mymetalbusinesscard.com